- 161 Whitney Place Fremont, CA 94539

- contact@testinghouse.com

- 510-580-3070

What Is Boundary Scan?

This process, known as boundary scan, is helpful in testing circuit boards. Through boundary scan, any printed circuit board can be tested and examined for its basic powering up functionality. The best part of boundary-scan is that it does not need and specific or dedicated test stations or fixtures. This method comes in handy in a number of places, especially for designers and engineers who can test or debug any product without having the physical need for any test probes. This method has gained immense popularity in recent times, and it can be used as a tool to test and support an electronic product over the period of its complete lifecycle. This process can also be useful in cutting down the costs and production time which can be really beneficial for the manufacturers and eventually the end-users for getting a quality product with a decent price tag.

At Testing House, our testing experts, including designers, engineers, and developers, build test solutions and test them through various modern techniques and processes, one of which is Boundary Scan, which lets them check the power-up functionality of a printed circuit board. Through our testing services, you get the comfort and convenience, and surety about the test results – consistently.

Why Choose Our Boundary Scan Services?

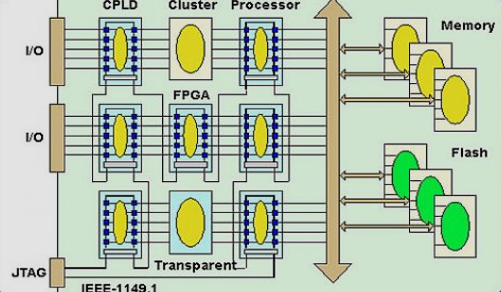

With our Boundary Scan services, you get the surety of expertise and command over the process and a promise to deliver what we commit. We not only use this method for our production stages but for others as well, throughout the lifecycle of the product by using the latest IEEE-1149.1 that further makes it efficient and practical and reduces the production cost and time too.

Benefits of Boundary Scan

No need for test fixtures. Integrates product development, production test, and device programming in one system. Test and Programming data can be reused in Production. Fast test procedure development. Reduced inventory management. Eliminates or reduces ICT usage time. Pre-production testing can begin as soon as prototype is released.

- Use During the All Phases

- Check Power Up Functionality

- Low Production Costs

- Less Time Consumption

- Easy to Carry Out

- Reduced Design Changes

- Functional Tests